BRAZED BTA DRILL

What is BTA Drilling?

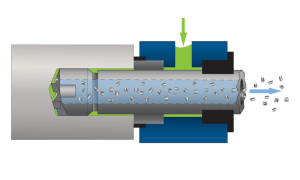

BTA deep hole drilling is used for larger hole drilling, typically 20 – 200 mm [0.80 – 8.00 in] in diameter High-pressure coolant is introduced around the outside of the tool through the pressure head assembly Chips are discharged through the tool center, through the drill tube and machine spindle

BTA drilling typically performs 5-7 times faster than gundrilling, and requires higher power

Additional extended diameters can be drilled on BTA machines with secondary deep hole operations, such as counter-boring

There is 2 types of drilling which are DTS systems and STS systems. We will only focus on STS systems as all our TOTIME drill heads are for STS system.

The BTA—STS Drill is a single Tube Drilling system used in Deep Hole Drilling applications where fast metal removal is needed. Drill sizes in BTA Drills are from 0.312”-2.559” diameter. New drills are manufactured in a number of grades to fit individual customer requirements. BTA (STS) Drills of brazed construction can be re-tipped in our plant to an “as new” condition at a significant cost reduction and savings to the customer. These drills require high pressure coolant to flush the chips through the tube to the chip box. The STS may also be referred to as the BTA system in the deep hole drilling process.

TOTIME BTA drilling offers you the best quality made in Japan and can successfully replace BTA drills heads from major makers such as Taegutec and Unitac, etc. TOTIME BTA drilling heads also offers you a longer tool's life with less cost. Please refer to one of our test report in our news column. TOTIME BTA Drills 100% Original Japanese quality.

For more about TOTIME BTA drilling, please click the below link to download the English Catalog.

TOTIME BTA DRILL CATALOG DOWNLOAD.

If you are interested in testing TOTIME BTA drilling, please contact us soon.